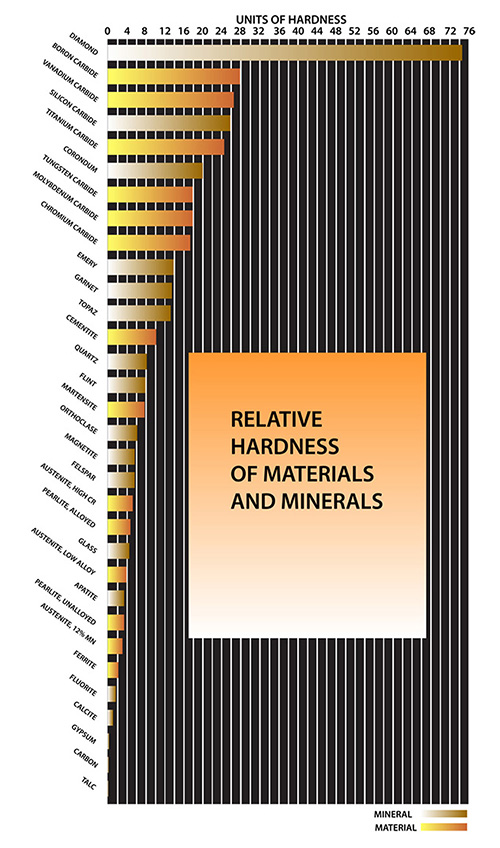

Achibale kuuma kwa Zipangizo ndi Mchere

-

- 1. Daimondi

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silicon carbide

- 5. Titaniyamu carbide

- 6. Corundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10. Emery

- 11. nkhokwe

- 12. Topazi

- 13. Cementite

- 14. Khwatsi

- 15. Mwala wamwala

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, Mkulu CR

- 21. Pearlite, Wogwira Ntchito

- 22. Galasi

- 23. Austenite, Low aloyi

- 24. Apatite

- 25. Pearlite, Wopanda Ntchito

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Kalciti

- 30. Gypsum

- 31. Mpweya

- 32. Talc

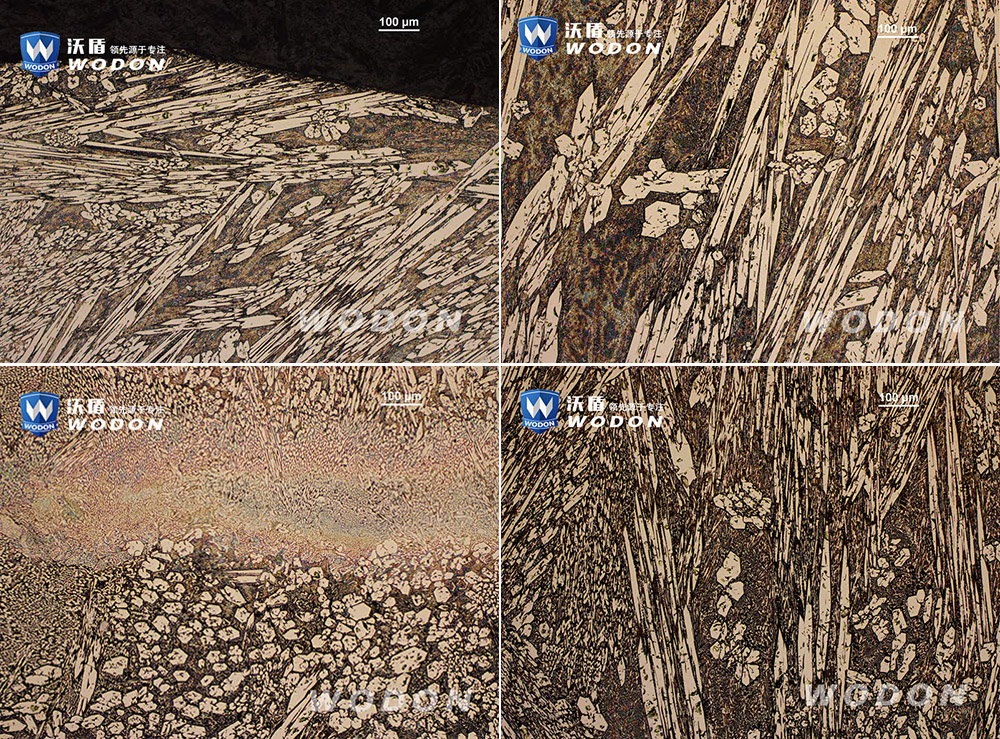

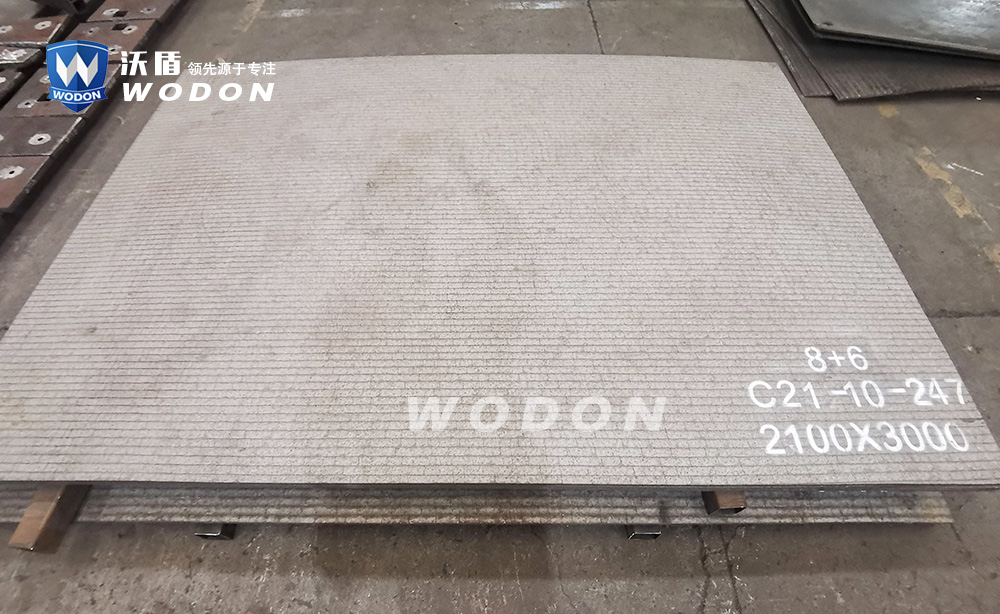

- Wodon ali apadera pakupanga mbale yophimba ya Chromium carbide, timakhala ndi ma teknoloji olowetsa arc omwe ali ndi zinthu zambiri za Cr kuyambira 25% mpaka 45%. kachigawo kakang'ono ka carbide kamene kali pamwamba pa microstructure kali pamwamba pa 50% ndipo kuuma kwakukulu kwa tinthu tating'onoting'ono ndi HV1800. methyl ASTM-G65 methode A ili pansi pa 0.16g.

- Mbale bimetallic Chromium Carbide:

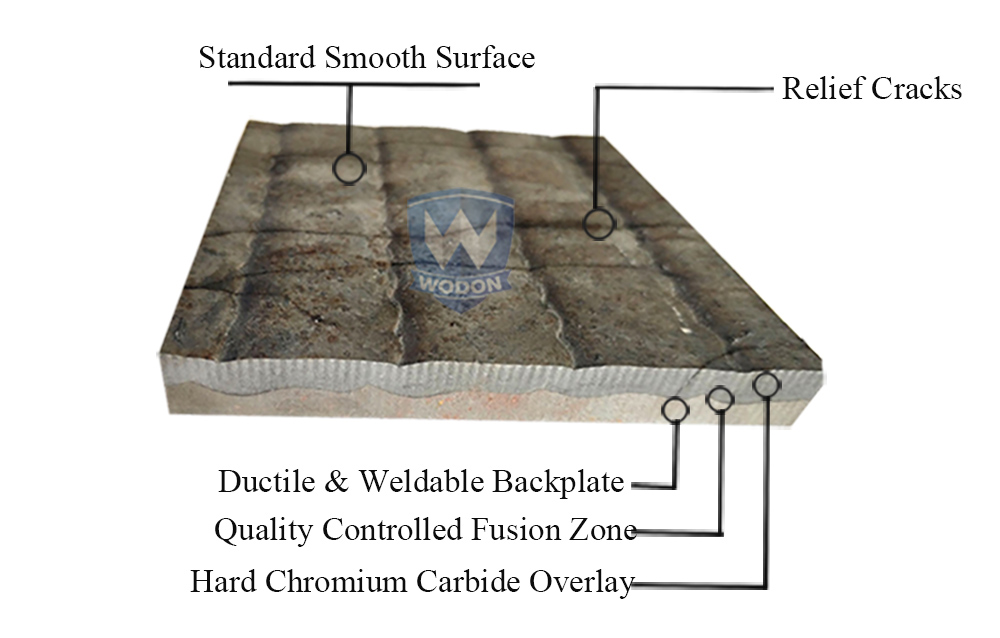

- Zamkatimu /Lchitsulo cha kaboni + Azigawo zosagonjetseka → Chromium carbide bimetallic mbale ndi chomangira chitsulo

- (Q235 / Q345B + Chromium Carbide wokutidwa → Chromium carbide bimetallic mbale Womizidwa arc kapena Open arc welding

- ukadaulo)

- Mwatsatanetsatane:

- Chovala chosagwira chimakhala ndi ma chromium carbide olimba kwambiri. Tinthu timeneti timagawidwa mosiyanasiyana m'mbali zonse, ndikupanga makina olimba kwambiri. Kuuma kwake ndi HRC 58~ 65 ndipo zimatengera makulidwe okutira.

- Zosakaniza zazikulu za mbale ya Wodon ndi C (%): 3.0 ~6.0 ndi Cr (%): 25 ~ 45. Gawo la mankhwalawa limabweretsa kuchuluka kwakukulu kwa ma Cr7C3 chrome carbide olimba. Kulimba kolimba (mpaka HV1800) kwa tinthu timeneti konsekonse kumatsimikizira kuti ndizovala zosavomerezeka.

- Kukutira ndi mbale yayikulu ndikulumikiza kwazitsulo. Chotsekeracho chimalowera mu mbale yoyambira pafupifupi 0.8 ~ 1.8 mm, kufikira 350 Mpa m'mayeso athu.

-

- WD1200 avale mbale itha kugwiritsidwa ntchito pochotsa kwambiritions.

- * Chromium carbide yokutidwa mbale kugonjetsedwa

- * Mwa kumizidwa kwaukadaulo kwa arc

- Kupanga Kwazida: C: 3.0-6.0% Cr: 25-45%

- * Chromium carbide Cr7C3 voliyumu yamagawo pafupifupi 50%

- * Makulidwe osanjikiza osalala amatha kufikira 50 mm

- * Kutentha kwamphamvu mpaka 600 ° C

- * Lager muyezo avale kugonjetsedwa malo 1400 * 3000mm, 1400 * 3500mm, 2100 * 3500mm

- * Bwino flatness ndi pamwamba yosalala

- * Kulimba: HRC58-65 (650-720HV)

- Mbale izi ankagwiritsa ntchito Migodi, simenti, Mphamvu, Malasha, Port, turbines Mphepo ndi makampani zitsulo.

-

Post nthawi: Sep-27-2021